Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

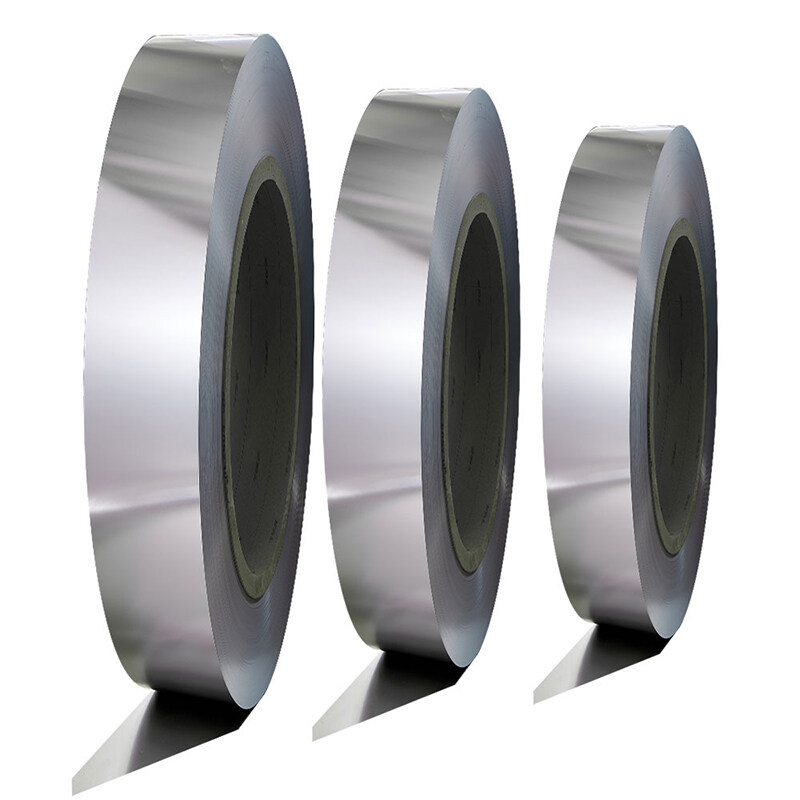

Hot cold rolled 301 Stainless Steel Plate sheet coil strip belt

We offer customization options for hot and cold-rolled stainless steel plates, sheets, coils, strips, and belts, allowing you to choose from a wide range of thicknesses and lengths. Our complete sales system ensures that we take responsibility for the entire production and sales process. Thanks to its strong anti-corrosion properties, our stainless steel is suitable for use in chemical and mechanical industries.

-

200series, 300series, 400series

-

1/4H, 1/2H, 3/4H, H

-

EH, SH

-

2B, 2D, TR, BA, HL

-

Brushed, SF, 4K-12K

-

Customizable

This is our 301304 304L 316 316L Hot cold rolled Customization Stainless Steel Plate sheet coil strip belt, any interests, plz feel free to contact us!

301 stainless steel is a popular austenitic stainless steel alloy known for its excellent corrosion resistance, high strength, and ductility. It is often used in various applications, and it can be manufactured in different forms, including plates, sheets, coils, strips, and belts. The terms "hot rolled" and "cold rolled" refer to the manufacturing processes used to produce these different forms of 301 stainless steel.

Hot Rolled 301 Stainless Steel:

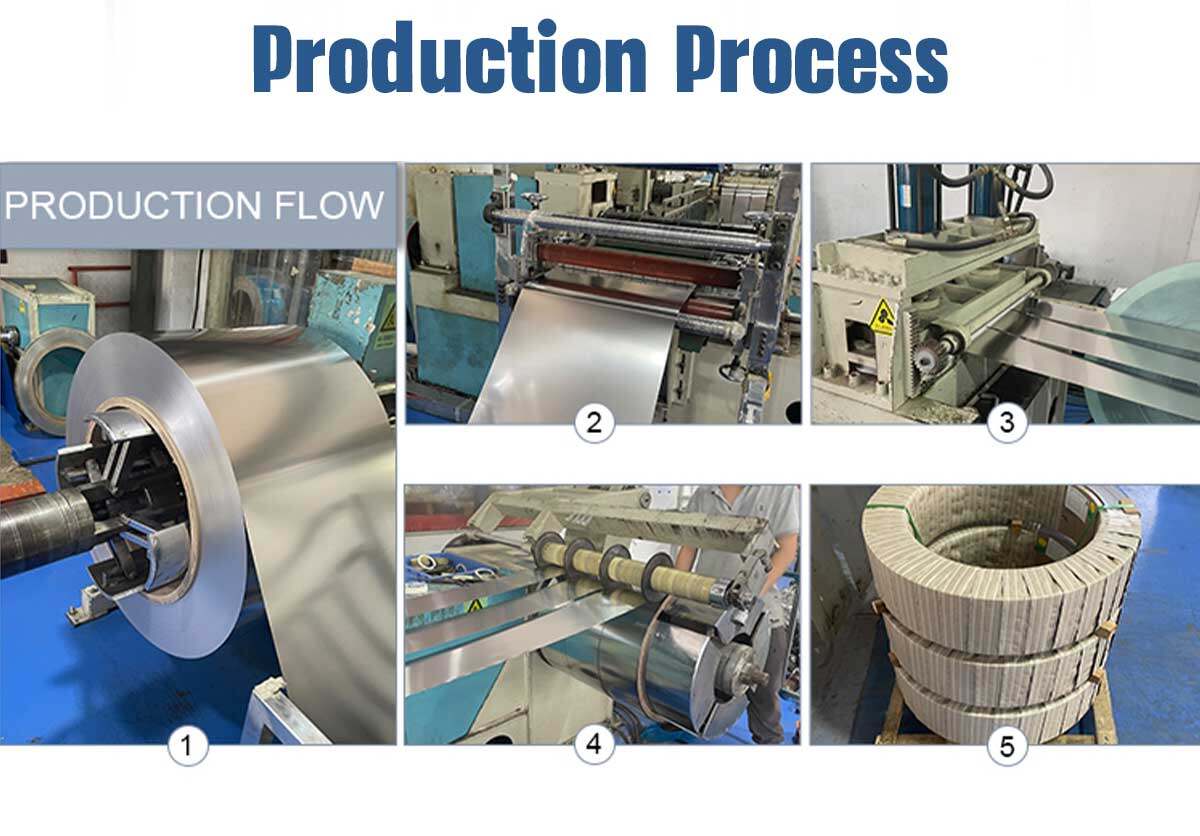

- Production Process: Hot rolling involves heating a metal to high temperatures and passing it through a series of rollers to achieve the desired thickness and shape. Hot rolled stainless steel is typically produced as larger, thicker plates or sheets.

- Properties: Hot rolled 301 stainless steel plates and sheets tend to have a rougher surface finish and may have less precise dimensions compared to their cold-rolled counterparts.

- Applications: Hot rolled 301 stainless steel plates are often used in structural applications, industrial machinery, and large components where a smooth surface finish is not critical.

Cold Rolled 301 Stainless Steel:

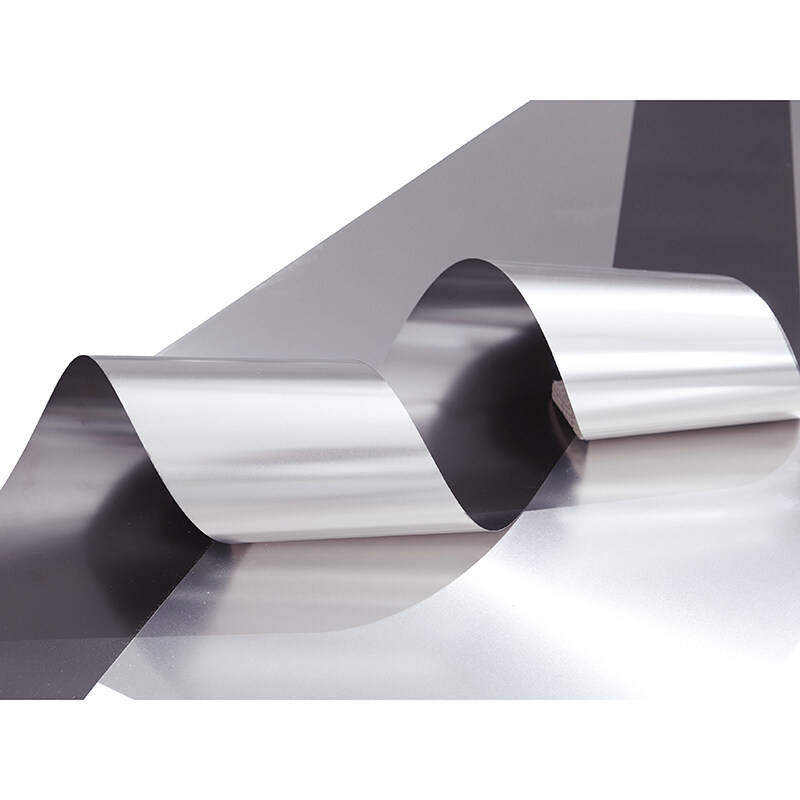

- Production Process: Cold rolling involves taking hot rolled stainless steel and passing it through a series of rollers at room temperature to achieve the desired thickness and shape. Cold rolled stainless steel typically results in smoother surfaces and tighter tolerances.

- Properties: Cold rolled 301 stainless steel sheets, coils, strips, and belts have a smoother and more uniform surface finish, making them suitable for applications where appearance and precision are important.

- Applications: Cold rolled 301 stainless steel is used in applications such as automotive parts, appliances, kitchen equipment, and decorative trim, where a polished finish and tight dimensional control are required.

Coils, Strips, Belts: 301 stainless steel can be produced in coil, strip, and belt forms. Coils are typically large rolls of stainless steel sheet, while strips and belts are narrower, more precise cuts. These forms are convenient for various manufacturing processes, including stamping, forming, and cutting.

The choice between hot rolled and cold rolled 301 stainless steel, as well as the specific form (sheet, coil, strip, or belt), depends on the requirements of the application. Factors to consider include surface finish, dimensional precision, and the intended use of the material.

Stainless steel is closely related to our life. We can see it everywhere in our daily life, such as stainless steel pots, bowls, ladles and basins. This depends entirely on its smooth surface, high plasticity, toughness and mechanical strength, and its corrosion resistance to acid, alkaline gases, solutions and other media. The advantages of stainless steel plate are mainly divided into physical properties, chemical properties, process properties and mechanical properties. Here are four advantages:

Advantages of stainless steel plates

1.Physical properties

Heat resistance, high temperature resistance, low temperature resistance and even ultra-low temperature resistance.

2.Chemical properties

The chemical and electrochemical corrosion resistance of steel is the best, second only to titanium alloy.

3.Process performance

Austenitic stainless steel has the best process performance. Due to its good plasticity, it can be processed into various plates, tubes and other profiles, which are suitable for pressure processing. Martensitic stainless steel has poor process performance due to its high hardness.

4.Mechanical properties

According to different types of stainless steel, the mechanical properties are different. Martensitic stainless steel has high strength and hardness, which is suitable for manufacturing parts that are both corrosion-resistant and need high strength and high wear resistance, such as hydraulic turbine shafts, stainless steel cutting tools, stainless steel bearings, etc. austenitic stainless steel has good plasticity and low strength, but the corrosion resistance is the best of stainless steel, which is suitable for occasions that need very corrosion resistance but do not require high mechanical properties, For example, the equipment materials of chemical plants, fertilizer plants, sulfuric acid, hydrochloric acid manufacturers, etc., of course, can also be used in military industries such as submarines. Ferritic stainless steel has moderate mechanical properties and low strength, but it is oxidation resistant and suitable for various industrial furnace parts.

Classification of stainless steel plates

Stainless steel plates are classified according to different standards:

1.Classification by thickness

It can be divided into: thin plate (0.2mm-4mm), medium plate (4mm-20mm), thick plate (20mm-60mm) and extra thick plate (60-115mm).

2.Classification by production mode

It can be divided into: hot rolled steel plate (steel plate formed by heating furnace) and cold rolled steel plate (steel plate produced by cold rolling process).

3.Classification by purpose

It can be divided into: bridge steel plate, boiler steel plate, shipbuilding steel plate, armored steel plate, automobile steel plate, roof steel plate, structural steel plate, electrical steel plate (silicon steel sheet), spring steel plate, special solar panel (Hairui special steel).

4.Classification by surface features

It can be divided into: silver white matte (no need for surface gloss), bright as a mirror (building materials, kitchen utensils), rough grinding / intermediate grinding / fine grinding / very fine grinding (building materials, kitchen utensils), hair line grinding (buildings, building materials), close to mirror grinding (art, decoration), mirror grinding (reflector, decoration).

5.Classification by steel structure

It can be divided into: austenite type (200 series, 300 series stainless steel), martensite type (403, 410, 414, 416), ferritic type (409, 430, 434 series stainless steel), austenite ferritic type (both austenite and ferritic stainless steel).

What we have

Floor space: more than 20,000 square meteres

Production capacity: annual production capacity of more than 10,000 tons

16 years experience: Focus on the precision metal alloy material industry for more than 16 years.

Our services

- Customers' Request

- Free Sample

- Special Surface Processing

- Second Treatment according to customer requirements, such as: surface, width, etc.

Logistics

Transportation: sea, land

Delivery time: 15-25 working days

Packing: plastic film inside, woven bag outsourced and transported in a custom wooden box.

FAQ

Q: What is the MOQ?

A: MOQ: 500kg.

Q: What is your delivery time?

A: 7-25 working days.

Q: What is the payment method?

A: 30% deposit is paid in advance before production, and the balance is paid before shipment

Q: Can you guarantee the quality of the product?

A: Yes, we can.

Q: Are you a factory or a trading company?

A: Industry and trade integration

Q: Where is your factory?

A: Room 101, Building B, No. 3 Education North Road, Yixin Community, Pingdi Street, Longgang District, Shenzhen, welcome to visit.

Q: Are custom services available?

A: Yes, they are available.

Q: Do you support OEM and ODM?

A: Yes.

Q: Why choose us?

A: We have a number of slitting, shearing, electroplating, painting, wire drawing surface treatment production lines, which can meet the needs of different customers, rich market resources, sufficient inventory, complete specifications, and a complete technical team.

Q: Does your packaging ensure product safety?

A: Yes, we adopt quality package.

Q: What information do I need to provide to get an accurate quote?

A: Please provide us with these information: material, hardness, surface, width, thickness.

Q: How can I get product progress without going to your company?

A: We provide one-to-one customer service.

Q: How can I deal with this if I don't receive the item?

A: We will have special personnel responsible for following up the logistics of the goods.

Q: How is your after-sales service?

A: The company will have special personnel responsible for following up the logistics of the goods.

Q: Can samples be ordered?

A: Yes, they can.

Q: How much is the sample fee, can it be refunded after bulk product?

A: Samples are free, so all no fees are refunded.

Q: Do you provide quality assurance?

A: Yes.

Q: Do you support providing samples?

A: Free sample (without shipping).

Q: What is the monthly supply capacity?

A: 1000 tons/month.